High insulation performance

SOFENGI Africa provides a wide range of thermal and acoustic insulation, including insulation for processes, equipment, and utilities in various industries (furnaces, chimneys, pipelines, ventilation systems, etc.).

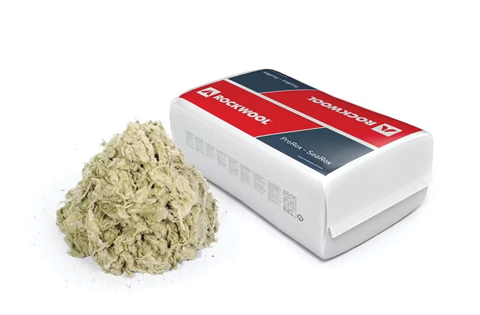

Rock wool is an excellent material. It has several advantages, including efficient thermal and acoustic insulation, incombustibility, and strong compression and chemical resistance. It is non-combustible, stable, durable, and environmentally friendly.

Rock wool therefore combines thermal efficiency, resilience to extreme conditions, fire safety, durability, environmental friendliness, and adaptability, making it an attractive choice for a wide range of applications.