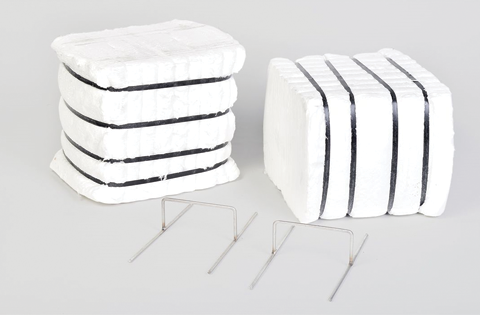

Ceramic Fiber CERAFENGI®

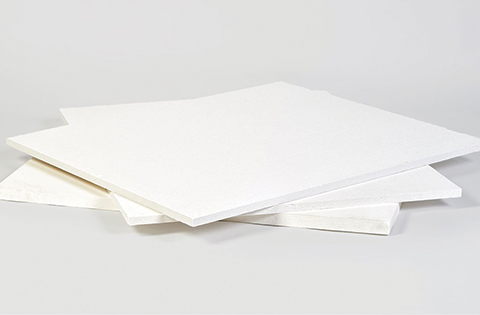

CERAFENGI® is a range of products produced from refractory ceramic fiber. Our products have been designed to operate constantly in extreme conditions (industrial thermal kilns, boilers, thermal shields, etc.).

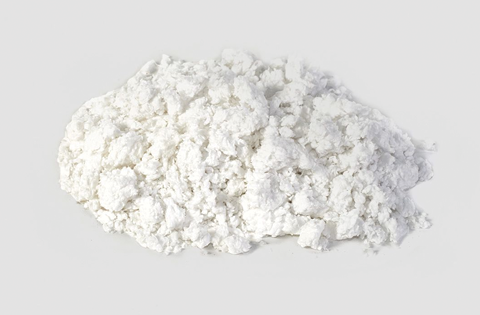

CERAFENGI® ceramic fiber's unique fibrous structure provides a unique combination of high thermal insulation, light weight, and high temperature resistance. Its outstanding flexibility, compression resistance, and low thermal conductivity contribute to its ability to restrict heat transport.

These features, along with excellent chemical resistance, make our CERAFENGI® fiber an ideal choice for improving energy efficiency, assuring fire safety, and satisfying the tough needs of industrial applications.