Industrial Tailor made textiles and joints

SOFENGI Africa provides an extensive line of products that have different chemical compositions and customized solutions to our clients' constraints in a variety of sectors, including:

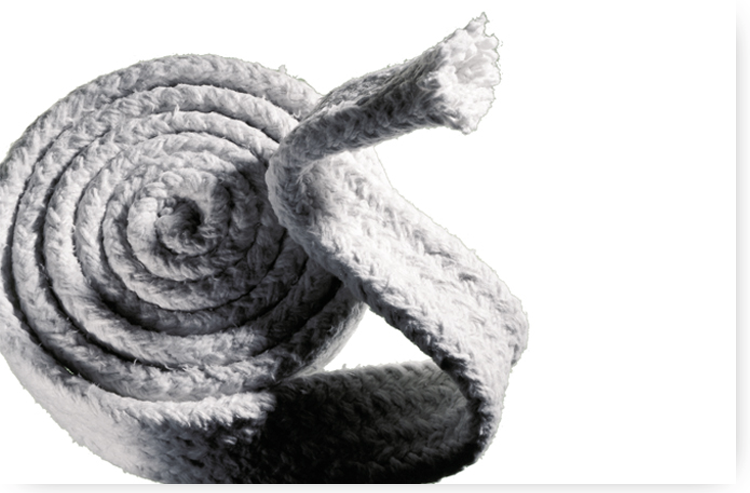

- Wide selection of ceramic fiber and fiberglass textiles, ropes and braids used for high temperature resistant linings and packaging.

- Industrial Seals

- Glass fiber reinforcement products (Woven roving, Mats, Surface veil, etc.)

Our collaborators and manufacturers are constantly developing and producing innovative fibers and inorganic materials that save energy, decrease pollution, and increase the safety and dependability of your projects.